ABOUT US

Suzhou Bao Forging Co., Ltd. is located in Suzhou, a beautiful historical city in China. It is a Sino-US joint venture forging company specializing in large and medium-sized forgings, covering an area of 35,351 square meters and a plant area of 1,4797.5 square meters. Baoye Forging has 2 tons, 6 tons of free forging electric hammer liquid, natural gas heating furnace, cover type electric furnace...

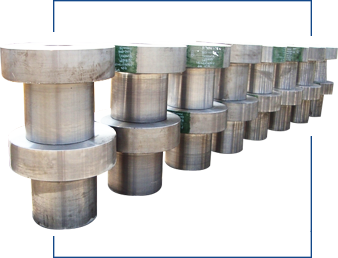

PRODUCT

Bao Forging pursues the operating principle of “Quality First, Customer First”, strictly implements national forging standards, establishes local area network within the company, and uses EPR system for production management.

CONTACT

ADD

Address: No.18 Changtai Road, Dongqiao Town, Xiangcheng District, Suzhou, China

Sales Department Email:zhang_jingyan@baoforging.cn

TEL

Tel:0512-65085929 / 65085936

翻屏组件设置面板

容器ID名称:#c_grid-16671990128220

关闭翻屏分辨率:768